Mini retort autoclave

for preserved food R&D

enabling flexible and cost-efficient R&D tests, pilot batches, and quality control

To food manufacturers, ALP offers compact autoclaves sterilizing & pasteurizing preserves for new product development. They make it flexible to conduct pilot studies, lab experiments, and small-batch production, without relying on large production equipment or external facilities. Streamline your development process with a cost-efficient solution tailored for small-scale needs.

New product feasibility studies

Testing of various packaging

Quality and microbiology control

Production of pilot batches

Trends in Food Processing

Retort food, meeting consumer demands for preserved ready-to-eat meals and sustainability, is increasingly popular for its ability to combine convenience, long shelf life, nutritional retention without preservatives, and its contribution to reducing food waste.

Using packaging such as pouches, trays, glass jars, bottles, and cans, retort food is sterilized or pasteurized with autoclaves to extend shelf life and to ensure safety, allowing for refrigerated or room-temperature storage.

Among these, retort pouch foods stand out for their lightweight practicality, driving innovation through thermal treatment and the multi-layered construction of pouch materials, which preserve fresh flavor and nutrient value.

ALP mini retort autoclave

To improve shelf life and safety, sterilize & pasteurize packaged foods under high temperature and pressure

- Ideal for food R&D, providing significant cost savings per cycle compared to industrial autoclaves.

- Counterpressure control prevents package breakage.

- Fast water cooling against heat denaturation of food.

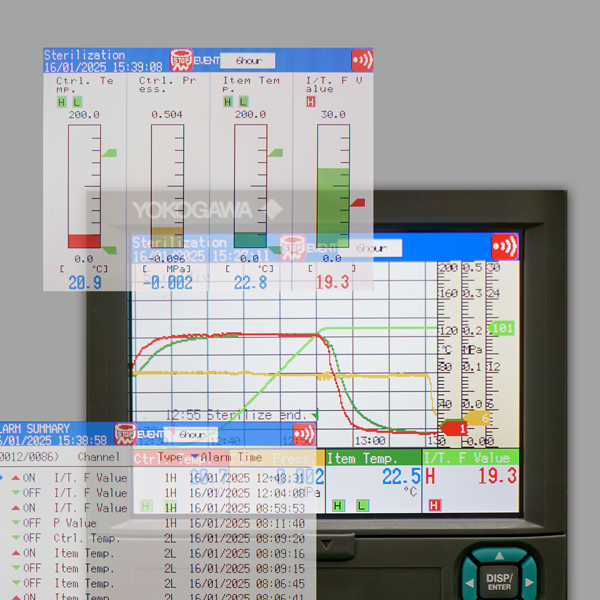

- F-value control system helps set optimal sterilization conditions.

- Steam or hot water sterilization, according to your preference.

- The RK-3030 model supports pouches, glass jars, cans, and special containers (e.g., plastic trays/bowls, jelly cups) with multi-stage pressure control.

- The RKZ-40II model is equipped with pasteurization/low-temp cooking (<100℃), useful for chilled foods (meat, fish, dairy, etc). It can process up to 40 pcs. of 200g stand-up pouches at once, making it ideal for pilot production.

- A vacuum packaging machine that strongly seals the pouch is available as an option.

- Abundant instruction videos and know-how content make operation easy for beginners.

What you can produce

Various kinds of packages

including glass jars, trays, bottles, cans, pouches or plastic containers

Sterilization

Heat to 100-121°C to kill heat-resistant bacteria, allowing for long-term storage at room temperature (1-5 years) without preservatives, while preserving flavor and nutrition.

Massa man curry (Thailand)

Bak kut teh (Malaysia / Singapore)

Nasi goreng (Indonesia)

Chana masala (India)

Sinigang (Philippines)

Ingredients of Pho (Vietnam)

Pasteurization

Heat to 60-99°C to kill specific microorganisms, enabling refrigerated storage for 1 week to 3 months while maintaining the original taste and texture.

Roast beef

Tandoori chicken

White-fleshed fish

Pudding

Fruits jam

Dairy foods

Why Choose ALP

ALP Co., Ltd. is a global manufacturer of mini retort autoclaves, providing high-quality, cost-efficient solutions.

since 1976

expert in science & medical equipment

for Client success

customization & durable products

from Tokyo

design, manufacturing, consultation

to 83 countries

global leader in mini autoclaves

Certifications

Client Voices

“As part of our business expansion strategy from just a Restaurant into Ready-to-eat meals, the machine has been a key success for the business as it allows our best-selling menus to be enjoyed by our customers anytime anywhere, 'Convenience never tasted so good'. We have since sold our products as daily convenience treats, gift hampers, and overseas takeaways, also available on the International Airport.”

Restaurant Baku Sayang

“We use the RKZ-40Ⅱ model for the development and small-scale production of hotel food. It can be placed in a corner of the kitchen, so it is easy to reach, and by starting the process when the ingredients are prepared, production can be done efficiently. In the future, we would like to package the ingredients that are popular at the buffet and sell them at the hotel front desk and on the EC site.”

Hotel in India

Free guide for retort food development

- Retort food development workflow

- How to set sterilization conditions

- Shelf-Life testing guidelines

Get Your Free Download

- ALP mini retort autoclave RK / RKZ series catalog

- Retort food development guidance

"*" indicates required fields