RKZ-40II

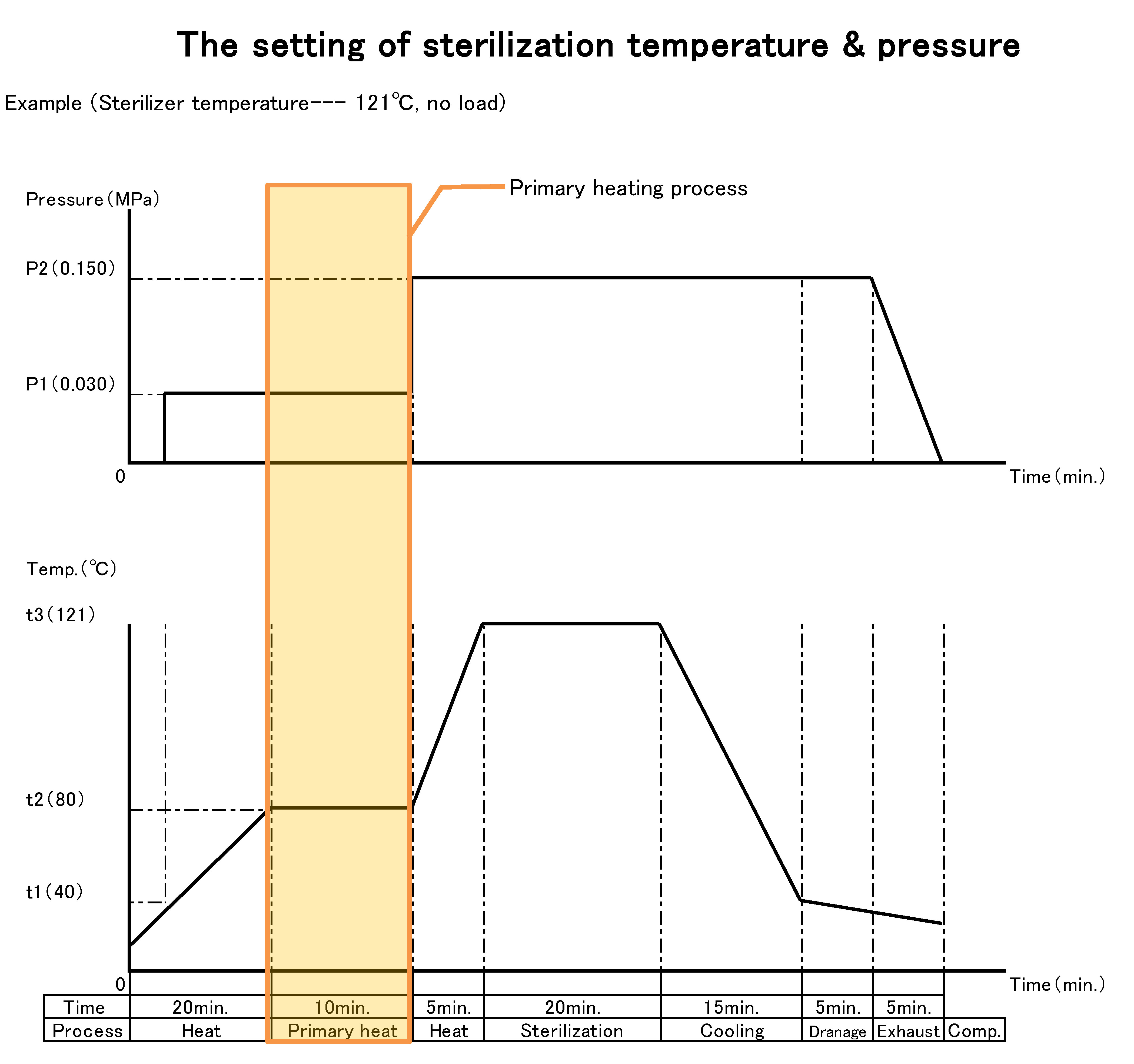

Significantly suppresses variation in F value due to the primary heating process

Eliminates variations in heat transfer that could not be achieved with conventional vertical retort sterilizers

We have greatly reduced this by providing our own primary heating process. Achieves uniform sterilization and suppresses uneven quality.

(Click to see the Enlarged view )

High pressure steam sterilization at 60 to 121℃ to pressurized cooling

High-pressure steam sterilization to pressurized cooling at 60 to 121°C can be performed safely and reliably without unevenness on a single unit for (liquid) food packed in pouches, jelly packs, glass bottles, cans, etc.

Digital recorder as standard

Build-in recorder records temperature measured by the item temperature sensor.

F-value operation is possible

In addition to F-value measurement, which is a necessary condition for retort sterilization, "F-value operation", which completes the sterilization process when the set F-value is reached, is possible. It is effective for finding setting conditions suitable for various sterilization substances.

Gentle pressurized cooling system

A gentle cooling system using a shower from a spray nozzle prevents wrinkling and deformation of the film.

Easy operation

Operation is fully automatic with the push of a button. Automatic water supply and drainage.

Additional purchase items are only baskets that match the form of sterilized items

All the functions necessary for retort sterilization are included, and it can be used simply by adding options (basket, tray, etc.) according to the form and insertion method of the sterilized product.