Multi Lab Clave CLG series

One-action safety interlock lid

One-action safety interlock lid.

Simply slide the lock lever one action to close the lid securely.

Double interlock system

Not only does it ensure that the lid remains closed during operation, but it also ensures that the lid remains locked until the temperature and pressure drop to a safe level.

64×24 High precision screen of dots

The settings etc. on an enlarged screen as shown below.

One - touch switching between the detailed and enlarged screen.

Air purge system by temperature/pressure calculation control (CLG series)

In addition to conventional temperature sensor control, pressure sensor control has been added to enable more reliable sterilization operation. When the pressure is high compared to the temperature, the pulse exhaust function works to create the optimum saturated steam condition according to the load capacity inside the chamber. In addition, it is possible to select the conventional air purge system (gravity displacement system) that operates according to temperature and time, so that the sterilization operation time can be shortened.

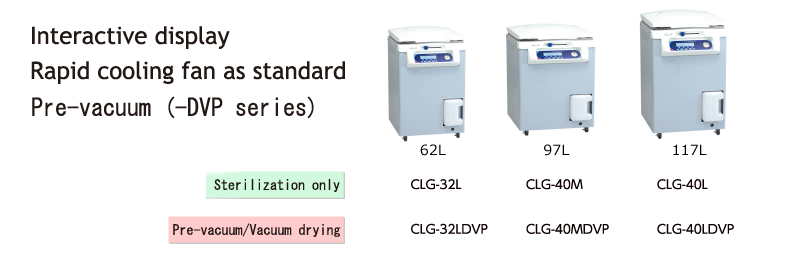

Air purge system by temperature/pressure calculation control plus pre-vacuum (CLG-DVP series)

In addition to the air purge system by temperature/pressure calculation control of CLG series-DVP series equip pre-vacuum function.

By repeating the cycle of air purging with a vacuum pump ⇒ filling steam and pressurizing ⇒ air purging again, residual air is strongly discharged.

Compared to the standard CLG-model, this allows steam to permeate complex-shaped sterilized objects such as various long tubes and special instruments used in the pharmaceutical industry more quickly, achieving effective saturated steam sterilization. increase. In addition, a wide range of settings can be made by selecting the pulse exhaust method or the gravity displacement method that does not use a vacuum pump like the standard CLG series.

Vacuum drying (CLG-DVP series)

Vacuum drying enables drying of the wet object by steam—air intake through 0.2μm sterilization filter.

Sterilization programs according to the object

Programs for objects to be sterilized are designed for easy operation. Programs are available for each object such as sterilization of liquids according to container shape, instruments, waste and dissolution.

Easy operation

Select program, then set objects in the basket to the chamber. Close the lid then press the START button to start automatic operation.

Large diameter of φ400mm

CLG-40M/L type uses a large-diameter Φ400mm chamber, giving it an outstanding capacity. Eight 500ml Erlenmeyer flasks and five 1,000ml Erlenmeyer flasks can be accommodated in the stainless wire basket. (Please refer to "Erlenmeyer Flask capacity" at the bottom of this page.)

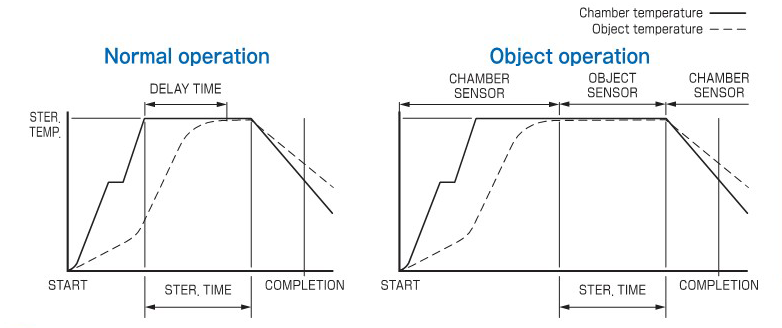

Temperature control by floating sensor * Cannot be retrofitted

Mount floating sensor in chamber then set or insert it near / in the object.

It is indispensable for the object which takes long steam penetration and temperature rise.

(Cannot be retrofitted, so please place an order at the same time as purchasing the main unit.)

Rapid cooling fan as standard

Cools the objects after cycle to shorten the time until unloading.

Optional accessories / functions

For accessories/options, we introduce options such as stainless steel mesh baskets, sterilization containers, temperature sensors, and printers.